Understanding the Process of EV Charger Installation

EV Charging 101 and the Roadmap for Installation

Electric vehicles change how we think about fueling: instead of detours to a station, charging happens where you park. That shift makes home and workplace installations central to convenience, cost control, and energy planning. A well-chosen charger can cut daily friction, lower running costs compared with liquid fuel in many regions, and set you up for flexible energy habits like using off-peak electricity. This guide connects the dots—from understanding charger types to navigating permits—so you can plan an installation that is safe, compliant, and matched to your driving pattern.

Outline of what you will learn:

– Part 1: How charging fits into everyday driving and what decisions actually matter.

– Part 2: Charger types and speeds, with practical comparisons of time and energy.

– Part 3: The installation process, from load calculation to final inspection.

– Part 4: Costs, incentives, and simple ROI math you can adapt to your situation.

– Part 5: Smart charging, reliability, and future-ready choices.

Why it matters now: EV adoption keeps rising, and charging infrastructure is following. Home users often find that Level 2 charging (240 V) turns sporadic stops into seamless routine—arrive, plug in, and wake up to a full battery. Workplaces, multifamily buildings, and small businesses can add charging to attract tenants, support fleets, or meet sustainability goals. Across these scenarios, the fundamentals are similar: understand power needs, wiring distances, panel capacity, and code requirements. The details—like circuit rating, conduit runs, and the choice between networked and simple plug-and-charge units—shape cost and performance.

At a high level, the process begins with a load assessment of your electrical service, followed by selecting the charger amperage that fits both your driving and the building’s capacity. Next come permits and installation details (circuit protection, grounding, cable routing, mounting height), then commissioning and inspection. Throughout, safety and compliance remain non-negotiable: EV charging is a continuous electrical load, so proper sizing and protective devices are essential. Think of the charger as a long-term appliance; choosing thoughtfully upfront pays back in reliability and peace of mind, and it opens doors to smarter energy use as your needs evolve.

Charger Types, Power Levels, and Real-World Charging Speeds

Chargers are commonly discussed by “levels,” which correlate to power and speed. Level 1 uses a standard household outlet (typically 120 V in some regions) at around 1.2–1.4 kW, adding roughly 3–5 miles of range per hour for many models, depending on efficiency. Level 2 generally relies on a 240 V circuit and can range from about 3.8 kW (16 A) up to 11.5 kW (48 A) or more, translating to roughly 15–45 miles per hour. Direct-current fast charging dramatically increases power—often 50–350 kW—but is usually suited to public sites or specialized private installations due to infrastructure needs.

How to choose? Start with your daily driving and parking patterns. If you drive 25–40 miles per day and park overnight, a mid-power Level 2 unit often refills the battery easily while you sleep. If you log longer commutes or share the charger among multiple vehicles, higher amperage may be helpful, provided your electrical service can accommodate it. For workplaces or multifamily sites, it’s often wiser to install several moderate-power ports with load management than a single high-power unit, because real cars spend more time parked than charging at peak power.

Key comparison factors:

– Power and circuit size: Higher amperage shortens charging sessions but draws more from your panel.

– Cable length and ergonomics: Longer cables add flexibility but require careful management to prevent wear and tripping hazards.

– Weather protection: Enclosures with robust ratings handle rain, dust, and temperature swings more reliably outdoors.

– Networked vs. non-networked: Connected units enable user authentication, usage reporting, remote updates, and dynamic load sharing; simple models are plug-and-charge with less complexity.

– Connector compatibility: Regional standards differ; verify that the plug and cable match your vehicle or that an appropriate adapter is available.

– Safety and certification: Look for units that carry recognized safety certifications for your region and include residual-current protection.

Real-world speed depends on two ceilings: the charger’s maximum output and the vehicle’s onboard acceptance rate. If your car tops out at 7.2 kW AC, pairing it with a 19 kW-capable unit won’t speed things up. Battery state-of-charge and temperature also influence charge speed; higher states and cold conditions often reduce rates. Because charging is dynamic, the most useful metric is time-to-target: how long it takes to reach your typical daily level (for instance, 80%). Matching that target to your parking routine is the surest path to a satisfying setup.

From Assessment to Commissioning: The Installation Process

Every successful installation starts with a site assessment. An electrician reviews your main service rating, panel space, and the distance from the panel to the charger location. EV charging is treated as a continuous load in many jurisdictions, so circuits are typically sized with extra headroom and protected by appropriately rated breakers. The installer also checks grounding, bonding, and whether your home or facility needs a panel upgrade or a subpanel to support the new circuit. For exterior runs, conduit type and routing must match environmental conditions, avoiding sharp bends and minimizing exposure to damage.

Typical step-by-step path:

– Load calculation: Determine if the service (often 100–200 A in homes) can support the chosen charger without nuisance trips.

– Permitting: Secure approvals from your local authority; requirements vary by location and may include drawings and equipment specs.

– Hardware selection: Choose a charger amperage and enclosure rating that match your site (garage, carport, exterior wall, or parking lot).

– Circuit installation: Install dedicated wiring, conduit, and breaker per code; verify torque on lugs and use proper strain relief.

– Mounting and cable management: Set appropriate height, add a hook or holster to protect the cable, and ensure clear access.

– Commissioning and testing: Confirm correct polarity, grounding, fault protection, and communication (for networked units).

– Inspection: A final review by the authority having jurisdiction validates compliance and safety.

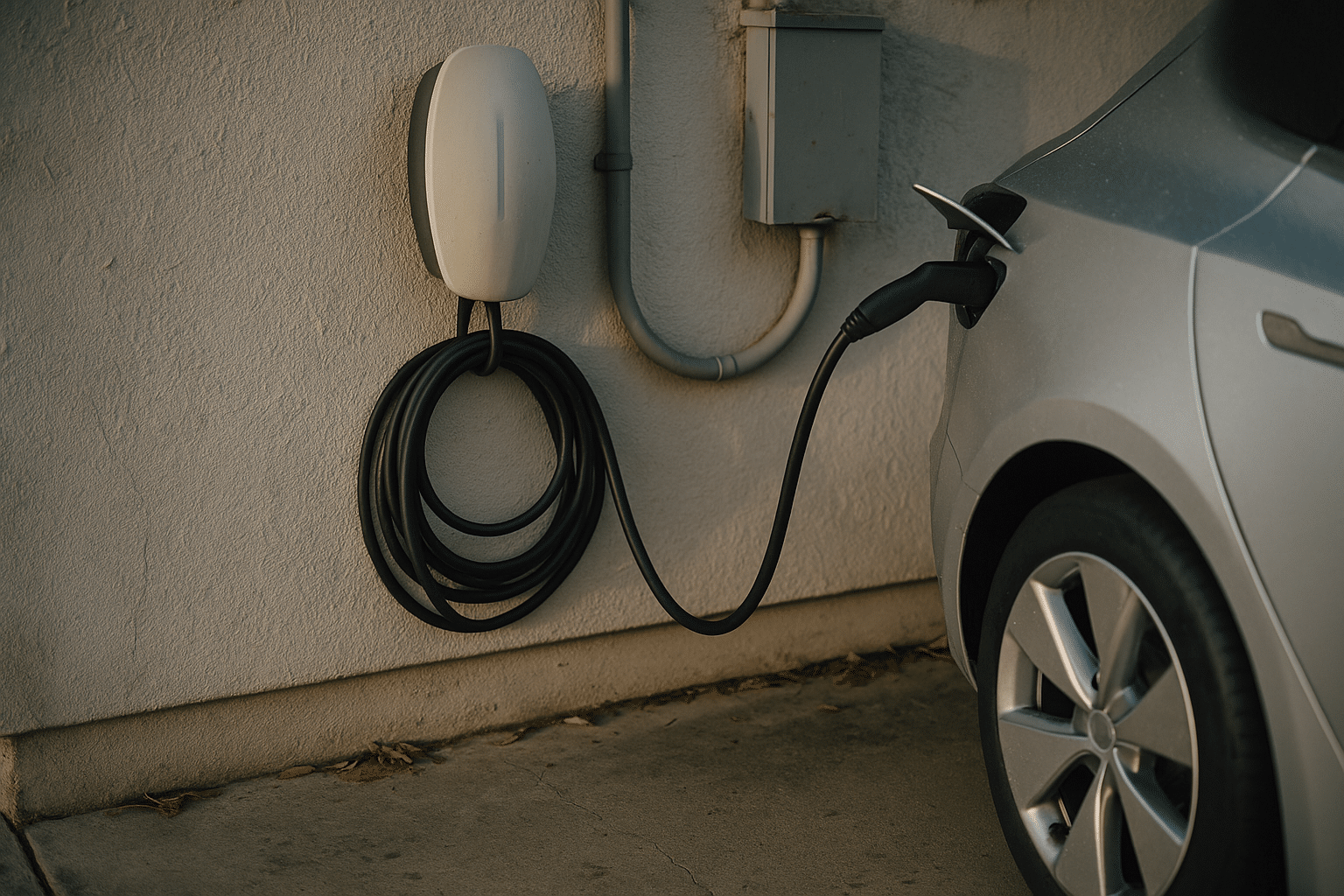

Home installs are often straightforward: a wall-mounted Level 2 unit near the parking spot, on a dedicated circuit, with a secure holster to keep the cable off the floor. Detached garages or carports may require trenching or overhead runs; for those, weather-resistant enclosures and careful mechanical protection are crucial. In multifamily or workplace settings, planning scales up: think about shared electrical capacity, signage, accessibility, lighting, bollard protection, and bollard spacing to guard equipment without obstructing use. Load sharing can distribute available power among several ports, so a building can serve multiple drivers without an immediate service upgrade.

Safety anchors the entire process. Use equipment with recognized certifications, follow manufacturer clearances, and confirm residual-current or ground-fault protection is active and appropriately rated. Keep cables off walking paths to reduce trip risks, and consider wheel stops or gentle cable guards where cars might roll over cords. Finally, document the installation—breaker size, wire gauge, conduit route, and configuration settings—so future upgrades or troubleshooting are simple. A methodical approach transforms a complex task into an orderly checklist that yields dependable charging day after day.

Costs, Incentives, and Practical ROI Scenarios

Budgeting for an EV charger involves a blend of hardware, labor, and sometimes upgrades. For many homes, Level 2 hardware can range from a few hundred dollars to over a thousand, depending on features like adjustable amperage, network connectivity, and enclosure rating. Installation costs vary with distance to the panel, the difficulty of the wire run, and regional labor rates. A simple interior installation near the panel might fall in the lower hundreds, while long runs, trenching, or outdoor protection can push the price into the low thousands. If a main panel upgrade is needed to expand capacity, costs may rise further.

Common cost components:

– Hardware: Charger unit, mounting kit, and optional accessories such as cable holsters.

– Electrical: New breaker, wire, conduit, fittings, disconnects, and protective devices.

– Labor: Assessment, installation, commissioning, and cleanup.

– Site work: Trenching, surface repair, bollards or guards, and weatherproofing.

– Permits and inspection: Local fees and documentation.

Incentives can significantly reduce net cost. Many regions offer rebates, tax credits, or utility bill credits for qualifying installations; some utilities provide special time-of-use rates that lower overnight charging costs. Workplaces and multifamily properties may access additional grants aimed at shared charging. Because incentives change, it’s wise to check your local energy office or utility before buying equipment. Even without incentives, spreading the cost over years of use can be reasonable, especially when electricity is priced favorably compared with liquid fuel.

A simple savings illustration: Suppose you drive 12,000 miles per year at an average efficiency of 0.30 kWh per mile. That’s about 3,600 kWh annually. At $0.15 per kWh, charging costs roughly $540 per year. If a comparable gasoline car averages 30 miles per gallon and fuel costs $4.00 per gallon, then 12,000 miles would consume 400 gallons at a cost of $1,600. In this scenario, the electricity saves about $1,060 annually. Actual results vary with driving style, climate, energy prices, and charging behavior, but the math shows why many drivers see meaningful operating cost reductions.

Two more considerations shape long-term value. First, reliability: a thoughtfully installed, properly protected charger reduces maintenance and downtime. Second, flexibility: choosing a unit that supports adjustable amperage or load sharing leaves room for future vehicles or added ports. Together with any available incentives, these choices help the project pencil out not only on day one, but across years of everyday use.

Smart Charging, Reliability, and Future-Proofing Your Setup

Smart charging adds brains to the brawn. Connected chargers can schedule sessions to align with low-cost hours, react to dynamic rates, and share power among multiple ports so circuits never exceed safe limits. For buildings, this orchestration can defer service upgrades by using what is already available more intelligently. For drivers, it means predictability: set a departure time and let the system handle when to pull energy. Usage data helps tenants, fleet managers, or homeowners understand patterns, track costs, and flag issues early.

Features to consider for longevity:

– Load management: Balance power across ports and cap total current based on real-time constraints.

– Open protocols: Interoperability eases future hardware changes and reduces vendor lock-in.

– Firmware updates: Security patches and feature improvements keep systems resilient.

– Energy integrations: Pairing with rooftop solar or home batteries can offset grid consumption and provide backup options.

– Access controls: RFID or app-based permissions can manage shared spaces without friction.

Vehicle-to-home and vehicle-to-grid capabilities are emerging, enabling a charged vehicle to support a residence during outages or contribute to grid services. While availability and regulations vary by region and model, it’s wise to monitor compatibility if backup power or grid participation interests you. Keep in mind that bidirectional use raises questions about interconnection requirements, warranties, and energy economics; these are solvable with planning, but they call for careful coordination with your installer and utility.

Reliability is as much about environment as electronics. Outdoor equipment benefits from sturdy enclosures, protected cable routing, and thoughtful placement that avoids puddles, snow banks, and direct sprinkler spray. In regions with heat or cold extremes, choose equipment rated for the temperatures you expect and leave slack in the cable so it flexes without strain. For coastal or dusty areas, regular inspection and gentle cleaning can extend life. Document passwords, network settings, and breaker locations, and plan a simple quarterly check: inspect the cable for nicks, confirm the holster holds the plug securely, and verify that scheduled charging still matches your utility’s off-peak hours.

The future of charging is distributed and quietly efficient: many moderate-power ports, coordinated by software, delivering energy when it’s most available and affordable. Investing in solid installation practices today sets you up to take advantage of that future. With a charger matched to your needs, clear documentation, and an eye on evolving features, your charging routine becomes almost invisible—just a steady hum in the background while life moves forward.

Conclusion: Turning a Good Plan into Everyday Convenience

If you are weighing EV ownership or looking to make charging more convenient, the installation process is your lever. Start with a realistic view of daily miles, choose a charger that meets that need, and size the circuit with safety in mind. Get permits in order, follow a clear checklist, and lean on qualified professionals for load calculations and code compliance. Consider incentives, time-of-use rates, and smart features that turn electricity into a predictable, low-friction refueling plan. The result is a setup that feels simple every day because it was designed thoughtfully from the start.